Goonvean Fibres are reputable for mastering concrete reinforcement and refractory using quality fibres as ingredients. Fibres help improve the durability, strength, and performance of concrete and are typically known in the construction industry as FRC (fibre-reinforced concrete).

Concrete is one of the toughest construction materials that is found almost everywhere, on driveways, pavements, and more. It consists of strong, chemically inert particulate substances, also known as aggregates (such as gravel and sand). However, despite the strength of concrete, it is susceptible to cracks, shrinkage, and spalling.

Plain concrete has a high compressive strength of up to 4,000 psi in domestic and standard commercial buildings. However, concrete is surprisingly weak in terms of tensile stress, which is why it is reinforced.

Fibres for Concrete

We manufacture high-quality short-cut polyester, polypropylene, and nylon construction fibres for concrete and insulation applications. Our construction fibres are suitable for concrete mixes to minimise shrinkage, reduce cracks, and improve their overall green strength. Our fibres also add permeability to concrete, producing minuscule channels in the castable structure to aid drying and prevent explosive spalling.

Specifically, we focus on polypropylene fibres for concrete mixes after a recent case study we carried out. Polypropylene has many beneficial properties. In particular, Goonvean Fibres’ polypropylene characteristics include:

- Non-polar

- Translucent

- Extremely low density

- High chemical resistance

- Tough and flexible

- Resistance against fatigue

Concrete Reinforcement

Our AC3/60 6mm acrylic fibres are another suitable alternative for concrete reinforcement. Both our precision and short-cut fibres are suitable for various industrial applications. Due to their rigidity, they help prevent and repair cracking and avoid sagging and distortion in final products. Some of our acrylic fibres’ characteristics include:

- High rigidity.

- Resistant against chemicals and solvents.

- High heat resistance and melting point.

- Impermeable to gas.

- Acts as a moisture buffer by regulating the drying profile of a formulation and preventing over-drying and cracking.

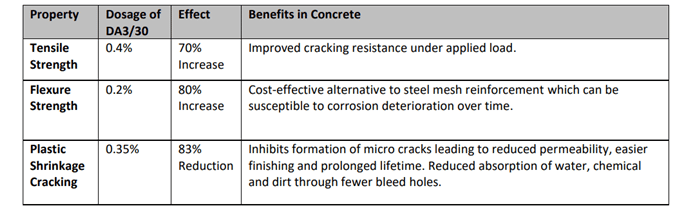

The results of our recent case study are below, documenting how our DA3/30 fibres had a positive effect when applied to concrete mixtures:

As shown above, the tensile strength and plastic shrinkage were drastically improved, while the flexure strength had an 80 per cent increase. This was based on our recommended dosage of 0.9kg/m3, approximately 0.1% by the weight.

Refractory Concrete

For refractory applications, our DA3/30 fibres will ensure permeable channels in the cast matrix formulate when applied to concrete mixtures. This helps increase its porosity and allows the vapour pressure to dissipate effectively, decreasing the risk of explosion. Our DA3/60 6mm fibres are also suitable for refractory applications, helping produce better quality, tougher, and more durable concrete to maximise the resistance against abrasion, cracking, and impact.

Not all construction materials require concrete reinforcements, but the majority do. It all comes down to the project’s overall structural limits and whether it requires strength and stability over a long period.

Fibre-reinforced concrete (FRC) is commonly used for large-scale construction projects that require maximum strength and durability to help stand the test of time, such as airport runways, industrial structural projects, and commercial establishments.

Order a Sample

We offer samples for all our fibres in several cuts and sizes. Our polypropylene fibres are available in:

- Short-Cut PP / 1.80 decitex and 3.30 decitex

- Milled PP Powders (Flock) / 90μm Particle size / <100 microns and 100 – 500 microns

Our acrylic fibres include:

- Precision Cut (3.3dtex) / 1.6-12.0mm lengths

- Precision Cut (6.7dtex) / 0.1-12.0mm lengths

- Milled Acrylic Fibre / 250μm – 12000μm Particle Sizes

If you’re interested in finding out more about our concrete reinforcement and refractory fibre ingredients, why not contact us? Alternatively, you can order some samples or put in a request. We are happy to tailor to your specific needs and requirements.