Back in the early 1920s’, people were not interested in the new and emerging synthetic fibres. Natural fibres were what every consumer wanted, such as cotton and hemp. So, the question is, when did synthetic fibres take over, what are their primary uses and what are their pros and cons?

Fast forward ten years later, Nylon was introduced as a solution to make cheaper alternatives to women’s stockings with greater durability and performance. Then, Rayon became a preferred, affordable alternative to silk.

From then on, the popularity of synthetic fibres grew dramatically – especially once we had the technology to identify the long and narrow molecules that make up the internal structure of natural fibres. Once this was discovered, scientists could replicate the formula and create their own, providing an affordable alternative with the ability to mass-produce. Although synthetic fibres have many advantages, they also have their downsides. The reason we have manmade fibres is because of sustainability and longevity, however, certain processes damage the environment due to the exposure of harsh and toxic chemicals.

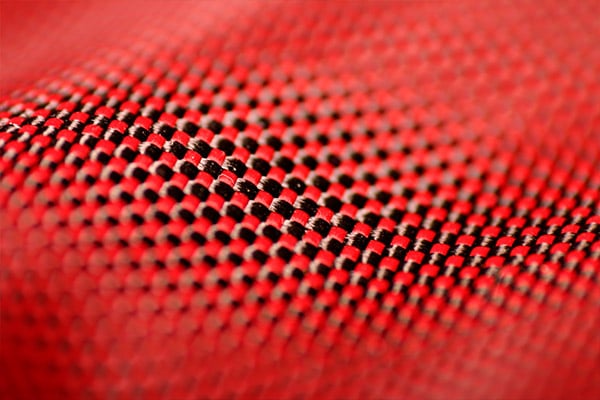

What Are Synthetic Fibres?

Unlike natural fibres which are from plants and animals, synthetic fibres are made up of chemical compounds. These compounds consist of either petroleum or coal-derived polymers or natural reoccurring materials modified by chemicals. The structure of polymers is described as multiple beads on a string, the beads representing individual units stringed together.

Manmade fibres are favoured because they are cheaper, have high tenacity and durability and come in two categories: cellulosic and non-cellulosic.

Synthetic fibres

Types of Synthetic Fibres

There are several types of synthetic fibres. Cellulose-based fibres include Acetate (cellulose acetate), Viscose Rayon (regenerated cellulose), However, these only represent a small fraction of the market’s needs. Non-cellulosic fibres, on the other hand, include Nylon (first synthesized in 1931), Olefin (1949), Acrylic (1950), Polyester (1953) and Spandex (1959) – making up most of the fibre market still today. Specifically, Polyester, Nylon, and Acrylic make up 80% of today’s market.

The Pros and Cons of Synthetic Fibres

PROS

There are many advantages to the use of synthetic fibres, depending on the fibre these can include:

- They are cheaper to make and buy which benefits mass production.

- Favoured for their waterproof properties.

- Long-lasting and significantly durable compared to natural fibres.

- Resistant against stains.

- They can withstand high levels of heat.

- Able to combat chemical degradation.

- Manmade fibres can easily tailor and adapt to applications by varying chemical composition.

CONS

Like most things, synthetic fibres also have their cons. Depending on the fibre these include:

- Prone to electrostatic charging when rubbed against other materials.

- Not always friendly to the skin and can cause allergic reactions.

- Manmade fibres are not biodegradable and therefore contribute heavily to soil pollution.