Fibres are used by a variety of industries for reinforcement, specifically polyester fibres. In paper applications, adding synthetic fibres improves the paper’s properties, primarily vastly improving the wet strength of the paper, allowing it to be used in wet or high-moisture environments without disintegrating. Other physical benefits are also seen including tear strength and drape. This is particularly ideal for medical paper applications, where the strength and drape are essential to keep equipment and environments clean and sterile.

In a recent case study, Goonvean Fibres found that our short-cut polyester fibres (also known as P2/60) provided several benefits to paper applications, with at least a 10 per cent increase in all the paper’s physical properties.

Short-cut Polyester

Polyester is a synthetic fibre made from petroleum-based chemicals. It was first produced in the 1930s and has since become one of the most widely used synthetic fibres. Goonvean Fibres’ polyesters come in several sizes to tailor to different applications. Our short-cut polyester is precision-cut for shorter lengths and a finer diameter filament.

How is Polyester Made?

Polyester fibres are made from a long chain of synthetic polymers. Polyester (also known as polyethylene terephthalate) contains purified terephthalic acid (PTA) and monotheluene glycol (MEG). Because polyester is a thermoplastic that can be melted and reformed, when polyester is made, polyester pellets (PET) are melted and fed through spinnerets. On the other side of the spinnerets, the polyester fibres solidify.

As a result, the fibres have no void spaces inside of them, which means they are continuous filaments that can be cut to any length to produce staple fibres for applications.

Fibre-Reinforced Paper

Fibre-reinforced paper (FRP) is a paper material in which fibres are embedded to improve strength and stiffness. The fibres used can be natural (wood, flax, hemp), synthetic (polyester, carbon, Kevlar) or a combination of both.

Polyester is often applied to paper to improve strength and durability. Polyester can be used to reinforce paper products, such as cardboard boxes and paper bags. It can also make composite materials, such as laminated paperboard.

Polyester is also an excellent reinforcement in paper recycling. Paper products that contain polyester fibres can be recycled more than those without polyester because the polyester keeps the paper from tearing and falling apart during the recycling process.

The Benefits of Polyester in Paper

Polyester is the most used fibre worldwide, accounting for half the overall fibre market and around 80% of synthetic fibres. Polyester reinforces paper of all kinds in applications such as regular and medical packaging, craft paper, filtration, and medical drapes.

The benefits of applying polyester fibres to paper include:

- Increases strength and durability, particularly when wet

- A lightweight nature

- Resistant to moisture and chemicals

- Wrinkle resistant

- Retains shape

- Stain-resistant, easy to clean and maintain

- Affordable and economical

- Absorbs moisture of all kinds and dries easily

Thanks to its strength, durability, and resistance to moisture and chemicals, short-cut polyester is a versatile fibre that can be used in a variety of paper applications.

Cellulose Fibres

A paper-based product contains 90-99% cellulose fibres, making them the primary structural element. These self-bonding fibres can affect the chemical and physical characteristics of paper products. At Goonvean Fibres, we use Vinyl Acrylic Binder to increase the degree of bonding between the cellulose fibre and synthetic fibre (polyester).

Cellulose fibres are created with ethers or esters of cellulose found in the bark, leaves, pulp, or wood of plants. They are also in the cell walls of fruits, vegetables, and other plant foods. Cellulose fibres have many positive effects in papermaking, and there are a vast number of plants that are potential sources of paper.

Polyester Fibres in Paper Applications

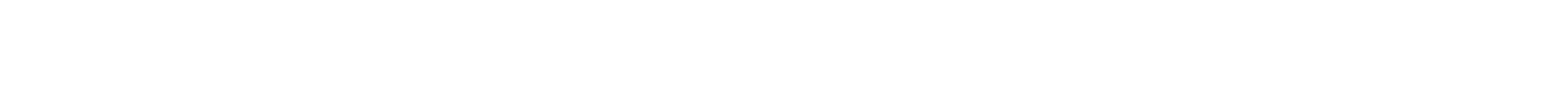

In Goonvean Fibres’ case study, we demonstrated the use of polyester fibres in reinforced medical paper applications. We tested the physical properties of medical crepe paper, including:

- Drape Ability (mm) – How the cloth falls or hangs. The higher the coefficient, the stiffer the fabric.

- Tear (mN) – The resistance of a paper sheet to tearing force.

- Dry Tensile Strength (kN/m) – Per unit width, the amount of force required to break the paper when it’s dry.

- Wet Tensile Strength (kN/m) – Per unit width, the amount of force required to break the paper when it’s wet.

- Wet Burst (kPa) – The pressure point at which a sheet of paper will burst.

The effects of adding our P2/60 6mm polyester fibres to a medical crepe paper formulation were thoroughly assessed and quantified, and the results were as follows:

- The Drape Ability had a 10% increase in the machine direction and an 18% increase in the cross direction, minimising microbial migration and infection.

- The Tear increased by 47% in the machine direction and 39% in the cross direction. The Dry Tensile Strength decreased by 18% under machine direction and 12% in the cross direction. These results helped to improve the resistance to punctures and tears to prevent microbial contamination of the sterile field.

- The Wet Tensile Strength increased by 108% in the machine direction and 121% in the cross direction. For the Wet Burst, there was a 140% increase in both directions. These results ensure that fluids can come into contact with the drapes, for example, during surgery.

To summarise, adding synthetic fibres to paper formulation improves performance in wet environments as well as tear properties and drape, further improving paper handling. In medical applications, this improves the prevention of microbial migration and contamination, which is essential for the health and safety of staff and patients.

If you’re interested in finding out more about our short-cut polyester fibres, why not contact us? Alternatively, you can order some samples or put in a request. We are happy to tailor to your specific needs and requirements.