Fibres have been used to improve the properties of rubber for a long time. Fibres also act as a cost-effective replacement for expensive components, such as carbon black. In this blog, we look at a specific fibre that we manufacture, PE60 polyester fibre, and how adding it to a standard Styrene Butadiene formulation can be beneficial.

What is SBR?

Styrene Butadiene Rubber (SBR) is an elastomeric copolymer that contains styrene and butadiene. It’s not to be confused with the thermoplastic elastomer Styrene-butadiene Block Copolymer, even though they derive from the same monomers.

Molecular structures of Styrene and Butadiene, the monomers of SBR.

SBR contains 75 per cent butadiene and 25 per cent styrene and is considered a substitute for natural rubber and benefits from getting harder over time rather than softer.

What are SBR’s Properties and Uses?

SBR is one of the cheaper, general-purpose synthetic elastomers often used instead of natural rubber. It can be produced by free-radical solution polymerization or emulsion polymerization.

SBR has several good properties, including:

- Resistance to aliphatic, aromatic, and chlorinated hydrocarbons

- High abrasion resistance

- Good ageing stability

- Resistance to emulsification in damp conditions

- Reduced shrinkage

- Increased flexibility

- Resistance to fats and mineral oils

In terms of usage, Styrene Butadiene Rubber is often used in applications for manufacturing tyres, conveyor belts, seals, adhesives, gaskets, hoses, timing belts, footwear, floor tiles, and more.

Fibres in SBR Formulations

Elastomer fibres provide flexible reinforcement in rubber compounds, ideal for products such as hoses, seals, transmission belts, and anti-vibration mountings. Short-cut fibres and flocks also improve the green strength and the hardness of unvulcanised rubber.

Several short-cuts or micronized fibres can be applied to SBR formulations, from cotton to polyester and nylon flocks, to increase flexibility, dispersion, and friction resistance. Aramid flocks can also be substituted where extreme temperatures are present and excessive wear resistance is paramount.

Goonvean Fibres provide fibres and flocks based on your wants and needs. We pride ourselves on offering a bespoke service and specialise in sourcing and processing natural and synthetic elastomer fibres for a wide range of industries worldwide.

Using Micronized Polyester to Improve SBR Elastomer Applications

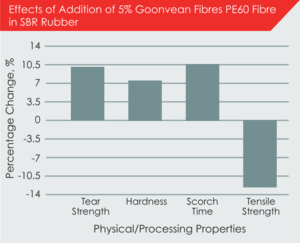

We conducted a series of tests by adding 5 per cent of our PE60 polyester fibre to a standard SBR formulation to quantify the benefits of using the fibre in rubber products. Polyester is a strong and resilient fibre that’s used in many industrial applications, as well as the textile industry. Polyester is flexible, resistant to stretching and shrinking, and resistant to abrasion and acid degradation. Because both SBR and polyester share similar properties, our technical team carried out an investigation to see how our PE60 polyester would benefit SBR elastomer applications.

The initial studies suggested that adding PE60 fibres to rubber formulations can improve processing and physical properties with the potential for cost-effective alterations to the formulation.

The Benefits of Adding PE60 to SBR Elastomer Applications

By adding our PE60 polyester fibres to the SBR elastomer formulation, we saw several improvements:

- Tear strength – The tear strength is how well the rubber resists the growth of a cut under tension. Here, there was a 10 per cent improvement when 5 per cent of PE60 was added, helping to prevent tearing.

- Hardness – The hardness property represents the resistance to permanent indentation. We calculated a 5-point (7 per cent) increase which improves cost-effectivity and has the potential to reduce carbon black dosage.

- Scorch time – The scorch time is the time during which the rubber compound can be worked at a specific temperature before curing starts. Here, there was an 11 per cent increase, which increased processing safety and had moulding benefits.

- Tensile strength – The tensile strength is the resistance of rubber to breaking under tension. Our results showed a 13 per cent decrease, however, this was highly anticipated by our technical team as the fibres don’t have a surface treatment that’s likely to interact with the rubber polymer.

Overall, our results suggested that our PE60 fibre helps to improve processing and physical properties, as well as cost-effectivity. The tensile strength remains above 20 MPa (megapascals), despite the decrease shown in the graph above, but this is more than sufficient for current applications.

If you’re interested in finding out more about our PE60 fibre for SBR formulations, why not contact us? Alternatively, you can order some samples or put in a request. We are happy to tailor to your specific needs and requirements.