Friction

Friction fibres are commonly added to friction products to increase durability, fade-resistance, and to extend the life of the components.

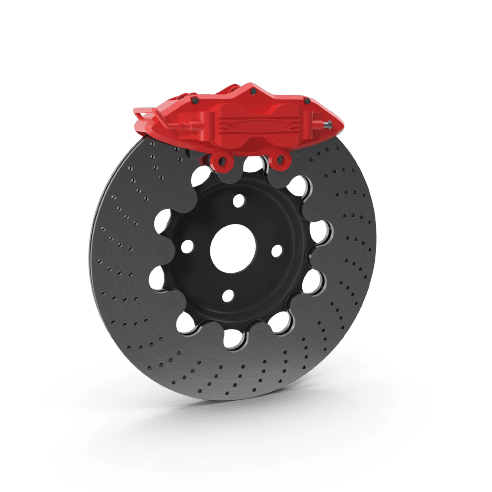

Friction components play an extremely important role in health and safety.

Brake pads and clutch plates are used to reduce speed and velocity of cars and machinery. Without them, the vehicle wouldn’t stop as expected.

Because they’re so important and these components see a lot of daily wear, tear, and constant use, the hardness and durability of friction components is vital.

Friction fibres are commonly added to friction products to increase durability, fade-resistance, and to extend the life of the components.

Brake Pads

Our friction fibres and flocks are widely used as reinforcement and process aids in brake pads and are used to add durability and longevity. The fibres primarily work by creating a “web-like” mesh, within the matrix of the formulation; to prevent components from settling out during manufacturing.

The following fibres and flocks are commonly used in the manufacture of brake pads:

< 500 microns Acrylic

1001 – 5000 microns Acrylic

Acrylic fibre flock is often used as a non-carcinogenic alternative to asbestos for the manufacture of brake pads and clutch plates.

It is extremely rigid and durable, resistant to solvents and chemicals, and has a very high melting point.

Due to the high melting point and heat resistance, it is a good choice for friction components which often becomes very hot.

< 500 microns Cotton

500 – 1000 microns Cotton

1001 – 5000 microns Cotton

Natural fibres are increasingly used to reinforce products in a growing number of applications, including friction components. Cotton is a very strong material which can add durability and longer life to brake pads.

500 – 1000 microns Aramid

1001 – 5000 microns Aramid

> 5000 microns Aramid

Aramids, such as meta-aramids like Nomex© & para-aramids such as Kevlar© are an extremely strong and durable material, making it an excellent addition to brake pads. It is extremely resistant to abrasion and chemicals and solvents.

Aramid also has a very high melting point and low flammability, so it can be used in hot environments such as friction environments.

Short cut aramid fibres and flocks are widely used as reinforcement and process aids (pre-form production) in friction products where high temperature and wear resistance are important. Aramid fibres are also used by gasket and seal manufacturers for use in aggressive environments.

< 500 microns

Composites are made up of individual fibre materials to provide a combined reinforcement solution for weight, strength, or cost reduction. Different combinations of fibres will give different benefits and properties.

Fibre composites have proven to be successful in the manufacture of brake pads, where a more expensive fibre has been partially replaced by a less expensive material without a significant reduction in performance.

Clutch Plates

Most clutches operate using friction, making them very vulnerable to wear and tear. Without reinforcement, they can wear down very quickly and need replacing often.

Various materials have been used for clutch plates, including asbestos in the past. Nowadays, clutches can be formulated with acrylic, aramid, and other materials to increase the strength and longevity of the plate. The fibres primarily work by creating a “web-like” mesh, within the matrix of the formulation; to prevent components from settling out during manufacturing

We supply the following materials for clutch plates:

< 500 microns Acrylic

1001 – 5000 microns Acrylic

Acrylic fibre flock is used in the manufacture of clutch plates due to its strength, durability, and high melting point.

Because acrylic is so strong, it can extend the life of the clutch plate and reduce the frequency at which it needs to be replaced.

< 500 microns Aramid

500 – 1000 microns Aramid

1001 – 5000 microns Aramid

> 5000 microns Aramid

Aramids, such as meta-aramids like Nomex© & para-aramids such as Kevlar© are one of the most common materials for reinforcement and strengthening. It is extremely durable and strong, as well as having a high abrasion resistance.

Clutch plates operate in high temperatures and very aggressive environments. Aramid is an excellent choice for this type of environment due to its durability.

Short cut aramid fibres and flocks are widely used as reinforcement and process aids (pre-form production) in friction products where high temperature and wear resistance are important. Aramid fibres are also used by gasket and seal manufacturers for use in aggressive environments.

< 500 microns

Composites are individual materials that are combined to get tailored benefits. For example, having an aramid and cotton composite might result in a stronger end product but one that is also eco-friendlier.