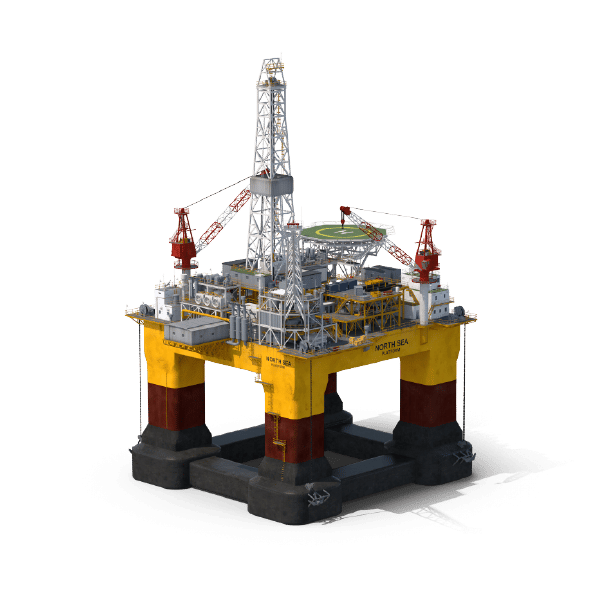

Oil & Gas

We manufacture a range of environmentally friendly products for the oil industry.

Our short cut fibres and flocks are used in the oil and gas industry for bore cleaning, as a case cleaning agent, and for filtration.

Fibres can also be used in sealant compounds for high temperature and pressure seals in aggressive environments where production downtime is not an option.

We specialise in the sourcing and processing of natural and synthetic fibres for a wide range of industries globally, which means that we have a lot of experience and expertise.

In a highly regulated industry such as oil and gas, our clients can rest assured that they are purchasing high quality, sustainably produced materials.

Find the right product for your oil and gas

Please use the configurator below so we can recommend a product based on your requirements.

Oil drilling

Fibres and flocks can also be used for cementing and acidizing, for both construction and as a debris cleaning agent. For example, acrylic is routinely used to aid construction of oil wells, and viscose is added to clean the wellbore, acting as a sweeping agent and collecting debris.

The following materials are used for oil drilling applications:

< 500 microns

Viscose rayon is a 100% biodegradable material but is extruded so is consistent and reliable. It is often used in oil drilling applications as it is strong and durable.

100 – 500 microns

Natural ground olive stones are organic materials ground to fine flours, granules, and pits. These inexpensive natural materials add an abrasive quality to cleaners and are often used in oil drill cleaning.

Filtration

Fibre flocks are used as pre-coats in wet filtration systems. They mask and bridge the open mesh in metal screens and loosely woven filter cloths. Flocks are easily dispersible and are able to coat the mesh evenly and handle strongly acidic or alkaline conditions. Precision or short cut fibres also reinforce non-woven mats and papers used in oil, air, and specialist filters such as dust masks and aircraft filters.

The following fibres and flocks are available for filtration applications:

0.95 decitex

3.30 decitex

28.00 decitex

< 500 microns

Viscose Rayon is a manufactured regenerated cellulose fibre. Cellulose flocks are resistant to cold weak acid and hot alkaline filtration liquids, and are suitable for filtering alumina plating solutions, silicates, and caustic solutions. Cellulose flocks also absorb microscopic impurities and 100% of the emulsified oil in boiler condensates. Because the flock has virtually no ash content, burning allows the metal and metal catalysts trapped within the filter flock to be reclaimed.

< 500 microns

500 – 1000 microns

1001 – 5000 microns

> 5000 microns

Polyethylene (or PE) is a flexible and strong plastic that is commonly used in oil and gas applications. It is resistant to chemicals and solvents and stable in cryogenic environments. It also has extremely good impact resistance, high fatigue and wear resistance, and zero water absorption.

Sealing compounds

There are several aggressive environments in which immediate maintenance is not possible, for example chemical transfer pipework. Sealing compounds are used to extend the life of pipework and to reduce the need for maintenance. Compounds containing short cut aramid and acrylonitrile fibres provide a seal that will withstand extremely high temperatures and levels of abrasion and corrosion.

These materials are commonly used in sealing compounds:

3.30 decitex

1001 – 5000 microns

Polyacrylonitrile (PAN) is a hard, rigid thermoplastic material that is resistant to most solvents and chemicals, slow to burn, and of low permeability to gases. It is often used for sealing compounds because of its fire resistant qualities and durability.

< 500 microns

1001 – 5000 microns

< 5000 microns

Short cut aramid fibres and flocks are widely used as reinforcement aids in a variety of products where high temperature and wear resistance are important. They are commonly added to sealant compounds because they are resistant to solvents and chemicals, nonconductive, very high melting point, and low flammability.

< 500 microns

Used in the same way as wool, our milled silk powder is perfect for protein extraction for enriched hair care products. It is excellent at smoothing any cells that overlap in a liquid formulation, making the end product feel smooth and luxurious.